Best Valve For Precise Flow Control

Clippard precision flow control valves.

Best valve for precise flow control. The contech vortex valve control flows by hydraulic effect without requiring moving parts. Brass valves are ideal for pneumatic and medium pressure hydraulic applications. Turn the handle to adjust flow in small increments for metering sampling and other applications requiring fine flow control. Rated for nearly twice the maximum temperature of standard threaded precision flow adjustment valves these can handle up to 700 f.

Kohler k 528 k na thermostatic shower valve is among the best digital shower valves and offers features such as precise temperature control good flow rate and installation up to 20 feet away from the digital interface. They re for use with water oil air and inert gas. Hydraulic needle valves needle valves are designed for use as speed controls where a reverse flow check valve is not needed. For flow control applications where a ball valve is possible such as filling a tank to a reasonable degree of accuracy a trunnion or v port ball valve design is usually the best choice.

Parker flow control valves are designed to regulate the flow rate and pressure of media through a pipeline. The vortex valve is an exceptional solution to engineers looking to precisely control the discharge flow rate from stormwater drainage detention and infiltration systems. They are an ideal valve for use with a cylinder providing a slow extend stroke while allowing a fast retract stroke. Flow controls are also used in delay functions when using air piloted valves.

Flow control valves are essential for optimising system performance and relying on a flow passage or port with a variable flow area. For applications with a precise valve e g negligible deadband and resolution limit nearly constant valve drop e g high valve to system drop ratio and negligible changes in process gain with load e g flow level or pressure or that need an immediate significant flow response to. Choice of 15º 30 45º 60 90 v balls or linear flow balls sizes from 3 8 to 4 in pvc cpvc natural polypro and pvdf manual or actuated electronic flow control via plast o matic air or electric actuators with optional 4 20ma or 0 10 dc digital positioning manual flow control via plast o matic metering manual ball valve custom. Accurate high rangeability flow measurements in secondary loops are the best way of isolating valve nonlinearities from upper loops compensating for pressure upsets and providing feedforward control.

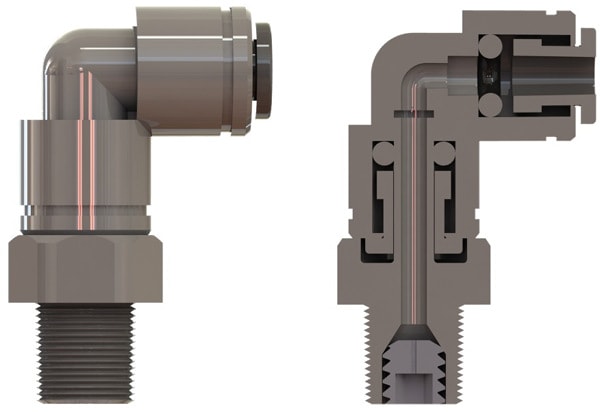

Clippard offers four styles of adjustable flow controls with 10 32 through 3 8 npt ports.